CIP variants

Cleaning of the fermenter is an integral part of the process in a research or production environment.

Depending on process requirements and manufacturing environment the cleaning process can vary greatly in terms of cleaning sequence, intensity, and procedure.

For small manually operated research fermenters it is often sufficient to clean only the vessel either by opening the lid or by introducing cleaning solutions via spray ball. For fermenters in GMP operation the cleaning process must involve not only the vessel but also the inlet and exhaust filter housings and the dosing lines. It must be reproducible and fully documented. Often cleaning requirements are somewhere in between these two procedures.

Bioengineering provides different CIP systems with various degrees of automation, sophistication and documentation for fermenters with full valve automation and CIPS/CIPR-function. Which of these is most suitable for the process is also a question of budget.

Common features of the CIP variants

The CIP variants are:

- CIP return pump

- CIP mobile manual

- CIP mobile automated

All three CIP variants start with the same procedure:

Connect hoses to the CIPS and CIPR connection points of the fermenter system.

Start the cleaning process as operation on the fermenter software. This opens and closes fermenter valves at defined times according to the programming of the cleaning process.

During the course of the cleaning process different areas of the fermenter system are released for the CIP media (cleaning agents, rinse water, WFI or air for blowout): Spray ball for vessel cleaning, inlet air line with filter housing and sparger, exhaust air line with filter housing and condenser, dosing lines, harvest valve group.

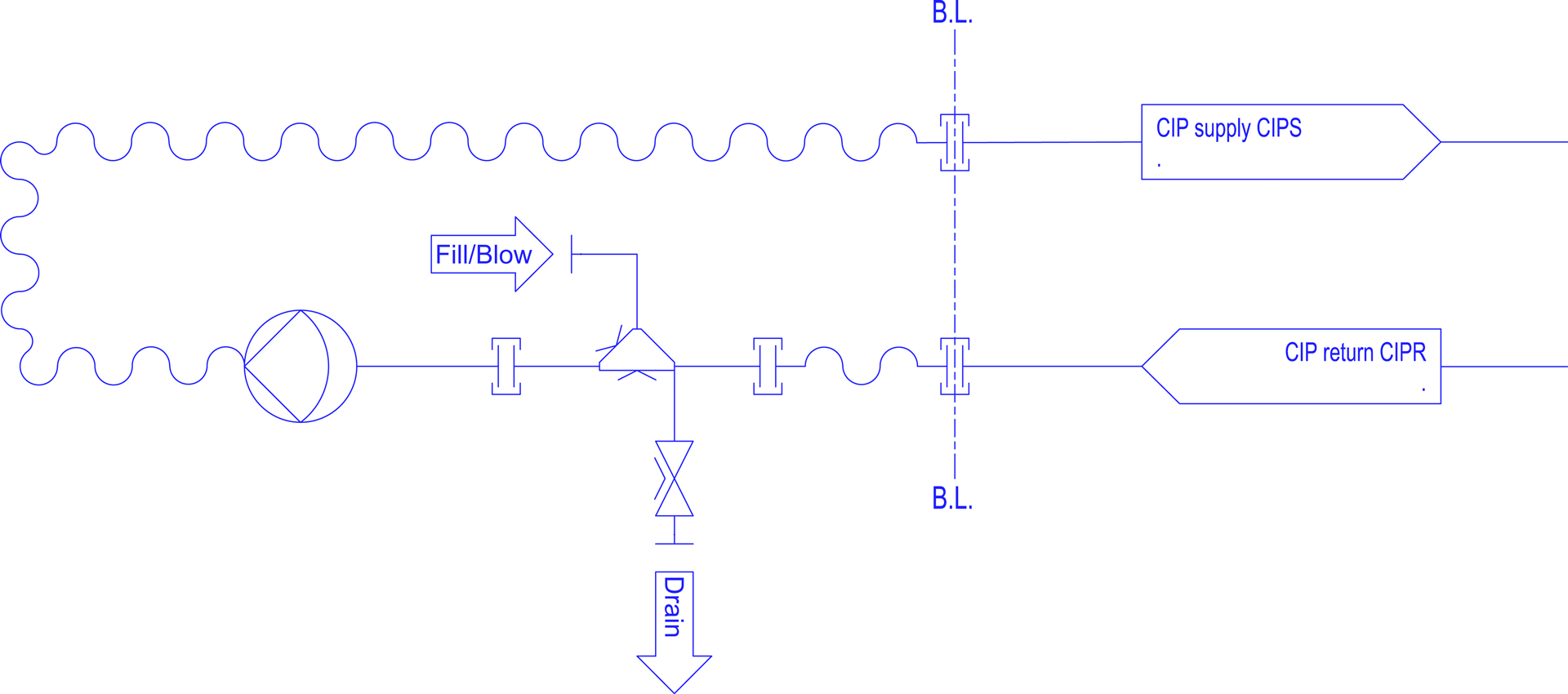

CIP return pump

The most simple CIP-system consists of a standalone circulation pump designed for the fermenter size it is used for and a manual valve cluster. Placement of the pump for optimum liquid inlet and drain is done by the user. The cleaning solutions are prepared directly in the fermenter vessel. The concentrate is filled into the vessel via lid port or dosing line from containers provided by the user.

The circulation pump is started manually at the same time as the CIP-program is started in the SCADA.

For each changeover of cleaning or rinsing liquid the CIP-program is paused and the liquid is drained manually via drain valve of the CIP return pump («DRAIN»). The vessel is then filled with fresh cleaning/rinsing fluid. For this purpose the valve «FILL/BLOWOUT» of the CIP-pump can be used. At the same valve-cluster pressurized air can be connected for blowout.

The program on the fermenter runs regardless of whether and which cleaning liquids are in the system, or whether the pump is running.

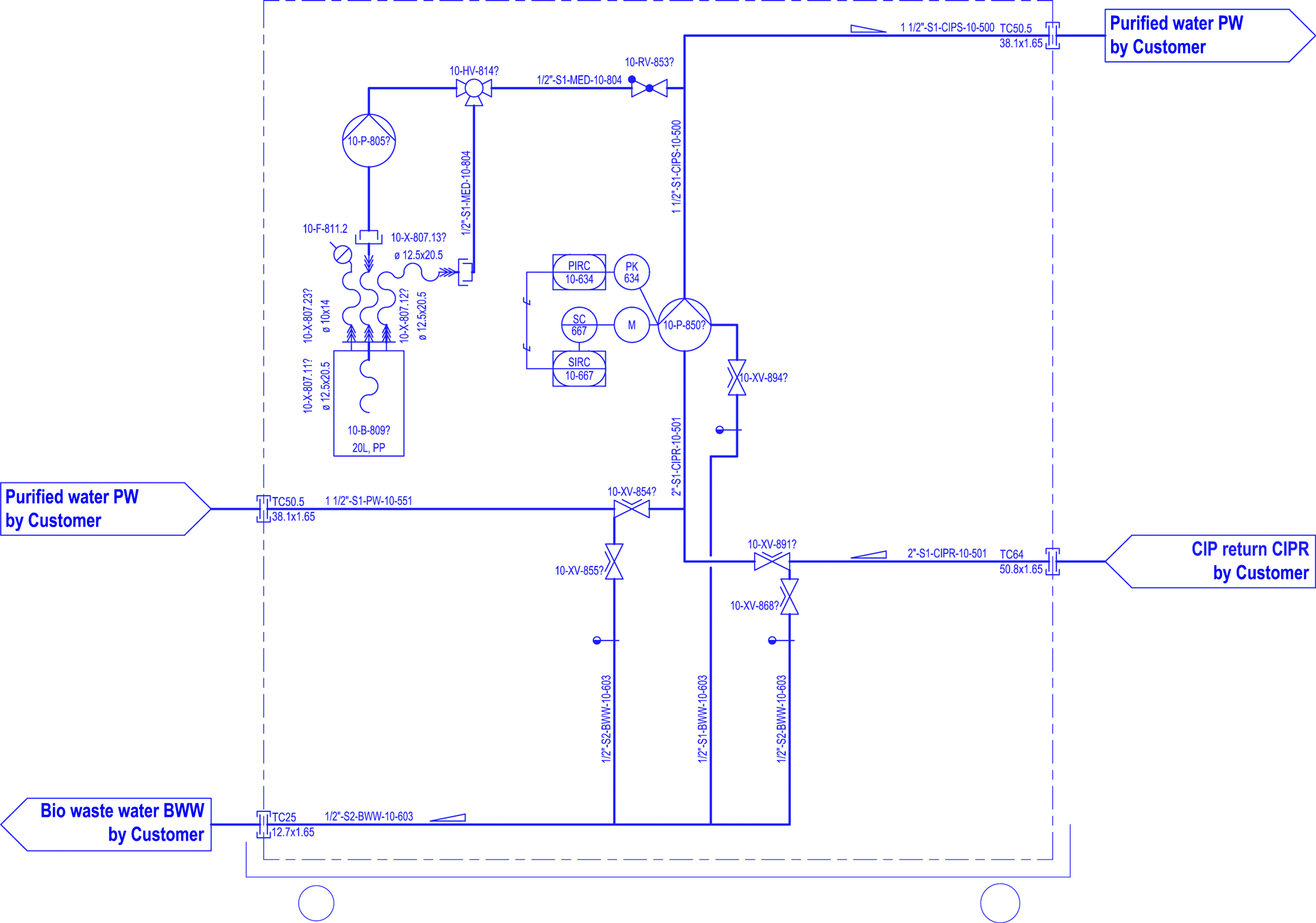

CIP-mobile manual

The manual CIP-mobile comes with a trolley and can easily be moved from one fermenter to the next or to storage. It is equipped with a container in which the cleaning concentrate is filled. The circulation pump has pressure and speed control and can therefore be used for different sizes and types of fermenters. The circulation lines are optimized for full self drainage.

When the CIP-program is started in the fermenter, the circulation pump is started manually. Water is provided to CIP-circuit and vessel via valve group of the CIP-mobile, a dosing pump allows for a defined addition of concentrate to the vessel.

The temperature of the circulating liquid can be adjusted as required via the fermenter control.

For each changeover of cleaning or rinsing liquid the CIP-program is paused and the liquid is drained manually via drain valve of the CIP-pump («DRAIN»). The vessel is then filled with fresh rinsing fluid, pressurized air for blowout or a new cleaning concentrate.

The program of the fermenter runs independently of the CIP-pump or if the cleaning fluids are connected.

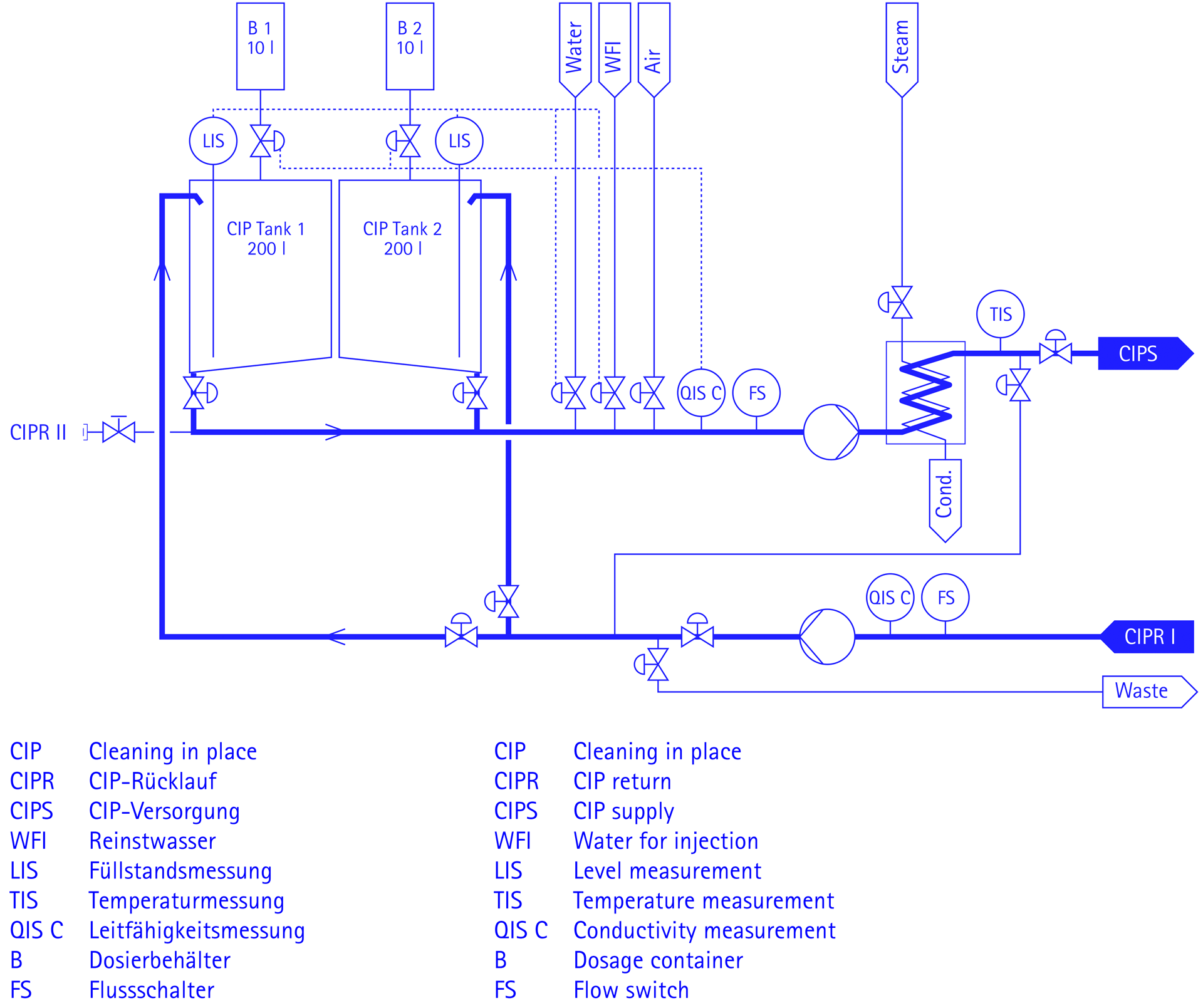

CIP-mobile automated

The automated CIP-mobile has its own control system. More than 40 automated operations can be selected and combined in recipes.

Cleaning fluids are mixed automatically according to the programming, supported by conductivity measurement in the mS range.

Temperature of the liquids is automatically brought to the programmed setpoint before being pumped into the fermenter and circulated.

Two 200L tanks for preparing and providing cleaning and rinsing fluids are available, as well as two 10L containers for the concentrates. There are separate connections for water, WFI and air.

A second conductivity probe in the µS-ranges determines rinsing time and cleaning success.

The cleaning program of the fermenter and the CIP-mobile must be started separately. Then the entire cleaning sequence of a recipe (e. g. pre rinse, cleaning, rinsing, post rinse and blowout) runs automatically and in coordination with the cleaning program of the fermenter without manual intervention of the user. All measurement data and sequences during a cleaning process are displayed and stored in the control computer of the CIP-mobile.