Power Transmission to Agitator Systems - Hygienically Sealed

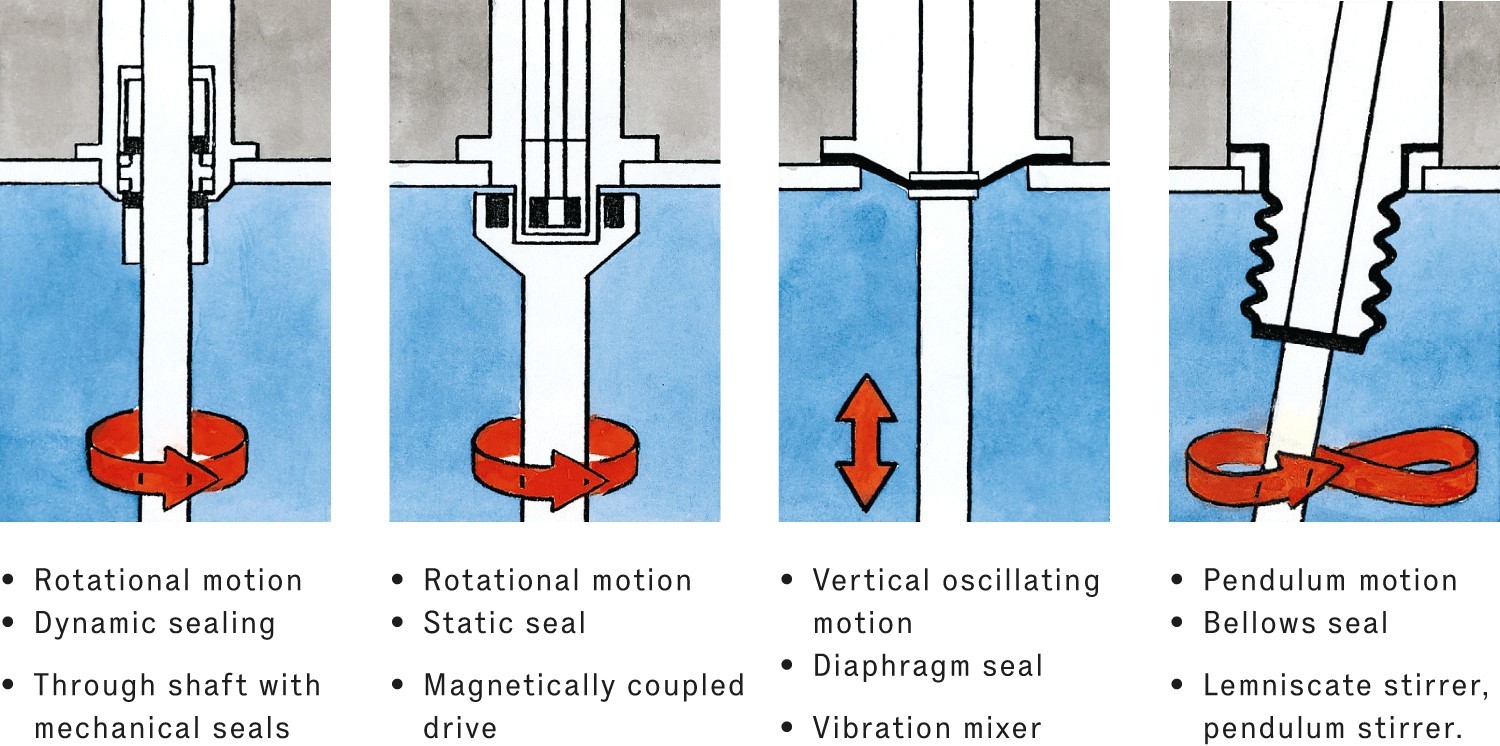

Liquids in reactors, media tanks and other process vessels usually have to be stirred. In hygienic processes, the main question here is how the driving force should be transferred from the outside to the stirrer inside the vessel without liquid escaping from the vessel or unwanted substances - including microorganisms - entering the vessel.

Transmission of the driving force directly via a shaft put through the vessel wall

This solution requires a sealing of the shaft against the vessel wall. In this case, the seal is always dynamic and friction occurs in the sealing element.

Since simple stuffing box seals are anything but hygienic, especially due to their high porosity, only the mechanical seal is suitable for sterile and hygienic applications.

The mechanical seal consists of a stationary sealing ring connected to the vessel wall and a rotating sealing ring connected to the shaft. The contact surfaces of these rings are absolutely flat and polished, thus preventing the passage of microorganisms through the sealing gap. At least one of the two sealing rings is made of a particularly hard material such as silicon carbide.

Mechanical seals are usually overlaid with a liquid in order to provide a film between the contact surfaces acting as lubricant to prevent the seals wearing out from friction. With a bottom drive, this can be directly the liquid in the tank, as is usual with benchtop fermenters. With a top drive, even with small benchtop fermenters, this must be a liquid outside the vessel on the other side of the seal. Typically, glycerin is used for this purpose.

With every mechanical seal, system-related, a minimum liquid leakage must be accepted when shafts are rotating. Frequently, this leakage is so minute, that it evaporates immediately and will not be visible. However, solids and microorganisms cannot pass through an intact mechanical seal.

In order to reduce the probability of microorganisms passing through the seal and also to reduce the passage of liquid through the seal in the event of a defect, a double mechanical seal is often used for larger fermenters. In this case, the space between the two pairs of sealing rings is superposed with a sealing liquid.

The sealing liquid is fed into the space between the seals via a small container.

In simple fermenters with unproblematic microorganisms, about 80% glycerine is usually used as sealing liquid. This liquid prevents the growth of unwanted microorganisms and evaporates only very slowly. Such a mechanical seal overlaid with glycerine can be implemented at low cost.

With greater technical effort, however, the gap can also be superposed with sterile steam condensate. This solution also allows in-situ steam sterilization of the space between the two sealing ring pairs before or during a process. The possibility of steam sterilization of the gap is common when GMP recommendations must be followed and especially when pathogenic organisms are cultivated.

A direct shaft allows the transmission of maximum torques. The system is therefore particularly suitable for microbial cultivations which have a high oxygen demand and therefore also require high stirrer performance.

In addition, a drive with a mechanical seal can be easily cleaned.

Transmission of the driving force via a magnetic field

With this solution, no shaft is guided through the vessel wall. The shaft with the agitators mounted on it is completely inside the tank, a dynamic seal is not necessary. However, the shaft and bearing must be positioned completely inside the vessel.

The power of the drive motor is not transmitted directly via mechanical elements, but only via a magnetic field through the vessel wall to the shaft in the vessel.

Leakage is impossible as long as any existing static sealing elements, e.g. O-rings, are undamaged.

Since this shaft bearing, often two or even three bearings per shaft, is located inside the vessel, there are inevitably more or less large dead spaces within the process liquid, e.g. the gaps between the bearing bushes or between any guide shaft and the actual rotating shaft. These zones can only be designed with considerable design effort to ensure satisfactory cleaning. The magnetic drives of Bioengineering are optimized with regard to good cleaning capability.

A magnetic drive only allows the transmission of limited torques. Very high stirrer performances cannot be introduced into the reactor vessel with this system. For this reason, magnetic drives are more likely to be used for cell cultures where typically only low speeds are used.

Transmission of driving force directly via non-rotating mechanical components

Stirrer solutions in which the driving force is transmitted directly to the stirring element via a non-rotating mechanical component, usually a rod, through the vessel wall are rarely in demand and used.

Instead of a rotational movement, an oscillating vertical movement is generated or a pendulum movement is extended, ideally to a lemniscate-shaped movement.

Typical representatives of the drive type with vertical oscillating movement are vibration mixers.

Systems with pendulum movement are not available as a standardized solution.

Both systems do not require a dynamic seal; leakage is only possible if the static seal elements fail. The sealing elements consist of elastic diaphragms or bellows made of metal or plastic. Dead spaces caused by design, which make cleaning difficult, can thus be avoided.

However, high drive powers can only be transferred to the process with a great deal of technical effort, if at all. Such systems are also not implemented as bottom drives and are therefore less user-friendly and service-friendly because of the large amount of space they take up on the lid, as well as requiring a crane to lift also for small vessels when they have to be opened for cleaning or service.

Bioengineering basically offers all solutions. Rotating drive systems with mechanical seals are the most frequently used, followed by magnetically coupled systems.

Bioengineering AG is happy to advise users on the choice of the most suitable system.